In order to determine the #tariff subheading, I always recommend knowing the product in detail and remembering that the effectiveness of a #nomenclature intended for the identification of #goods lies in the fact that it must include all of them and that each merchandise can only be classified into a single place.

It is important to remember the existence of #Merciological Nomenclatures allows us to identify a product more clearly by answering three questions: What is it? What is this fact about? and what is it for?

Synchronous belts, also known as timing belts, resemble a flat belt with evenly spaced teeth that are perpendicular to the axis of the belt.

The teeth of the belt are designed to grind against the teeth of the pulley, similar to chains. Timing timing belts do not rely on friction to transmit torque; Instead, they depend on positive engagement of the belt teeth with the sprocket teeth.

Depending on the requirements of an application, there are two main types of timing belts: rubber synchronous timing belts and polyurethane synchronous timing belts.

SECTION VII

PLASTIC AND ITS MANUFACTURES; RUBBER AND ITS MANUFACTURES

CAPITULO 39 PLASTICO Y SUS MANUFACTURAS

Note. 1. In the Nomenclature, plastic is understood to mean the materials of headings 39.01 to 39.14 which, when subjected to an external influence (generally heat and pressure and, where appropriate, the action of a solvent or a plasticizer), are or have been capable of acquiring a shape by molding, casting, extrusion, lamination or any other process, at the time of polymerization or at a later stage, a shape that they retain when this influence has ceased to be exerted.

In the Nomenclature, the term plastic also includes vulcanized fiber. However, this term does not apply to textile materials in Section XI.

Note. 2. This Chapter does not cover

l) synthetic rubber, as defined in Chapter 40, and articles of synthetic rubber;

CHAPTER 40 RUBBER AND ITS MANUFACTURES

Note. 1. In the Nomenclature, unless otherwise provided, the name rubber includes the following products, whether or not vulcanized or hardened: natural rubber, balata, gutta-percha, guayule, chicle and similar natural gums, synthetic rubber, factitious rubber derived from oils and all these regenerated products.

Note. 8. Heading 40.10 includes conveyor or transmission belts of fabric impregnated, coated, covered or laminated with rubber, as well as those manufactured with textile yarns or cords impregnated, coated, covered or sheathed with rubber.

Harmonized system nomenclature

40.10 CONVEYOR OR TRANSMISSION BELTS, OF VULCANIZED RUBBER.

– Transmission belts:

4010.35 — — Endless transmission belts, with notches (synchronous), with an external circumference greater than 60 cm but less than or equal to 150 cm.

4010.36 — — Endless transmission belts, with notches (synchronous), with an external circumference greater than 150 cm but less than or equal to 198 cm.

4010.39 — — Other

This heading includes conveyor or transmission belts entirely of vulcanized rubber, those of fabric impregnated, coated or laminated with rubber and those manufactured from textile yarns or ropes impregnated, covered or sheathed with rubber (see Note 8 of this Chapter). . It also includes vulcanized rubber belts reinforced with fiberglass fabrics, fiberglass or wire mesh.

Toothed (synchronous) drive belts (see illustration) are designed to transmit full power while keeping the rotation ratio between the pulleys constant.

The item as a whole is often referred to as a timing belt. The notches, commonly made on the inner surface of the belt, adapt uniformly to the grooves of the pulley.Synchronous belts do not have a trapezoidal cross profile

The straps of this item can be presented in the form of a collar (tube) that is cut to obtain the finished product. This form of presentation does not affect the classification

Note. 2. This Chapter does not cover

l) synthetic rubber, as defined in Chapter 40, and articles of synthetic rubber;

Classification

Conveyor or transmission belts that are presented with the machines or devices for which they are designed are classified with these machines or devices (Section XVI, mainly), even if they are not assembled.

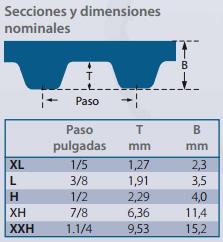

Strap dimensions

Other important aspects to classify

https://www.polybandas.com.co/images/stories/virtuemart/category/Sincrnicas.PNG

https://www.disfrutalasmatematicas.com/geometria/circulos.html

Minimum important descriptions to classify:

- Outer circumference: which is the length of the strap

- Constituent material: Example: unvulcanized rubber, unhardened vulcanized rubber, cellular rubber, non-cellular rubber, etc.

- Dimensions: Example: cross section dimension, length, etc.

- Type of finish: Example: ribbed, ribbed, printed, combined with textiles, reinforced with plastic, etc.

- Diameter of the outer circumference and shape of the section: In cm.

Fuentes:

https://import.medium.com/

https://co.linkedin.com/in/jeison-ruiz

https://muisca.dian.gov.co/WebArancel/DefResultadoReglasGenerales.faces

Gestor de sucursales, Profesional en Comercio Internacional con 8 años de experiencia en importaciones. Especializado en clasificación arancelaria, proyectos especiales y unidades funcionales. Amplia trayectoria en sectores, mineros, oíl & gas y energéticos. Asesor en restricciones administrativas y legales con enfoque en la preservación del ambiente. formación integral e interdisciplinaria